Roof flashing is a thin material, usually made of metal or rubber, that is used to prevent water from infiltrating the joints and valleys in a roof system. Flashing is installed in places where the roof meets a vertical surface, such as a chimney, vent pipe, or wall. It is used to direct water away from these vulnerable areas, preventing it from seeping into the structure.

Without proper flashing, water can easily enter the roof system and cause damage to the roof deck, rafters, and other structural components. Water can also seep into the walls and ceilings of the building, damaging the interior, potentially leading to the growth of mold and other organisms. In severe cases, water damage from a roof leak can compromise the integrity of the building, making it unsafe to inhabit.

By properly installing and maintaining flashing, you can help to protect your building from water damage and ensure that it remains in good condition for years to come.

What are the different types of roof flashing?

There are several types of roof flashing, each for different purposes and used in different locations on a roof:

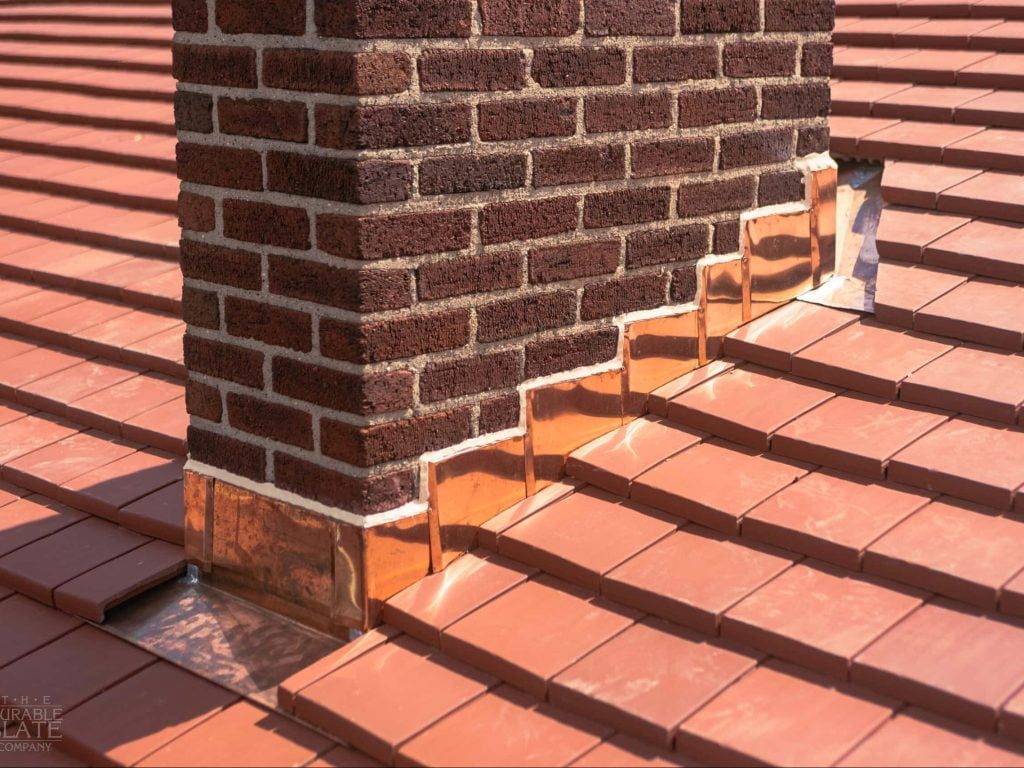

- Step flashing: Step flashing is used where the roof surface meets a vertical wall or chimney. It is installed in a series of overlapping "steps" that alternate from one side of the wall to the other, with each step covering the top of the one below it. This helps to direct water away from the wall and prevent it from seeping into the structure.

- Valley flashing: Valley flashing is used in the valleys, or the area where two slopes of a roof meet at an angle. It is usually made of long, continuous strips of metal that are installed along the entire length of the valley. Valley flashing helps to direct water away from the valley and prevent it from accumulating and causing damage.

- Chimney flashing: Chimney flashing is used to seal the area where the chimney meets the roof. It helps to prevent water from seeping into the structure around the chimney and causing damage.

- Pipe flashing: Pipe flashing is used to seal the area around pipes and other protrusions that pass through the roof. It helps to prevent water from seeping into the structure around the pipes and causing damage.

- Drip edge flashing: Drip edge flashing is used along the edges of the roof, where the roof surface meets the gutter. It helps to direct water into the gutter and prevent it from spilling over the edge of the roof and causing damage to the fascia and soffit.

What different materials are used for roof flashing?

Different materials commonly used for roof flashing, including:

- Copper: Copper is a durable and long-lasting material that is resistant to corrosion and weathering. It is also a good choice for flashing because copper can be easily formed and molded around corners and other irregular shapes.

- Aluminum: Aluminum is a lightweight and affordable option that is also resistant to corrosion. It is a good choice for flashing in certain conditions.

- Galvanized steel: Galvanized steel is a strong and durable material. It's steel that is coated with a layer of zinc to protect it from rust and corrosion. Galvanized steel is a good choice for flashing in areas with high levels of moisture, but it needs to be maintained by painting.

- Lead: Lead is a durable and long-lasting material that is resistant to corrosion and weathering. It is also a good choice for flashing because it can be easily formed and molded to fit around corners and other irregular shapes. However, lead is a hazardous material.

- Rubber: Rubber flashing is made from a flexible, waterproof material.

The Durable Slate Company favors copper flashing because it is aesthetically complimentary to other natural roofing materials, such as slate and clay-tile, and is similarly durable.

The advantages of using copper for flashing include:

- Durability: Copper is a highly durable material that can withstand extreme weather conditions and last for many years. It is resistant to corrosion and weathering, so it won't rust or deteriorate over time.

- Longevity: Copper has a long lifespan and can last for decades, even in harsh weather conditions. It is an investment that can pay off in the long run by requiring fewer repairs and replacements.

- Beauty: Copper has a distinctive, attractive appearance that can enhance the look of a building. It can add character and charm to a structure and is often used on historic or high-end buildings.

- Malleability: Copper is a soft and pliable material that can be easily formed and molded to fit around corners and other irregular shapes. This makes it an ideal choice for flashing that needs to be installed in hard-to-reach areas or around complex architectural features.

- Resistance to mold and fungus: Copper is naturally resistant to mold and fungus, so it is less likely to harbor these organisms compared to other materials. This can be especially important in damp or humid climates where mold and fungus growth can be a concern.

- Ability to be soldered: Copper is easily soldered with leaded or unleaded solders. We mainly use lead free solder in most applications.

How do I maintain my flashing?

Proper maintenance of roof flashing, no matter the material, ensures that it functions properly and protects the building from water damage. It is a good idea to inspect your flashing once a year to look for any signs of damage or wear. Look for cracks, gaps, or other openings that could allow water to seep through.

If you find any damage to the flashing, repair it as soon as possible to prevent leaks. This may involve patching small holes or replacing damaged flashing with new material. Tree branches that hang over the roof can rub against the flashing and cause damage. Trim any branches that are too close to the roof.

Dirt and debris can accumulate on the flashing over time; this can block water from flowing off the roof, damaging it. Clean the flashing periodically using a soft brush and a gentle cleaning solution.

Special note: The flashing is not designed to support the weight of a person - avoid walking on it whenever possible.

What should I look for in a flashing contractor?

When considering a contractor for flashing repair or installation, there are several factors that you should consider:

- License and insurance: Make sure your contractor is licensed and insured. This will protect you in case something goes wrong during the repair or installation process.

- Experience: Look for a contractor who has experience working with your type of flashing and roofing material, and that they are familiar with different types of flashing materials and installation techniques.

- Reputation: Check the contractor's reputation by reading reviews and asking for references. This will give you an idea of the quality of work that you can expect from the contractor.

- Price: Get estimates from several different contractors to compare prices and make sure you are getting a fair price for the work.

- Attention to detail: Pay attention to how the contractor assesses the job and prepares a plan for the repair or installation. A contractor who is thorough and detail-oriented is more likely to do a good job.

- Communication: Make sure that the contractor is easy to communicate with and responsive to your questions and concerns. Good communication is key to a successful project, no matter the building.

In closing, flashing is an essential component of a roofing system. It stops water from infiltrating the joints and valleys in the roof, causing damage to the structure. It is important to properly install and maintain flashing so it to functions properly and protect the building from leak damage. Always choose a company that is licensed, insured, experienced, and has a good reputation. By taking the time to find a reliable contractor and by properly maintaining the flashing on your roof, you can help your building stay in good condition for years to come.