Reproduced with permission from the author. This article first appeared on traditionalroofing.com:

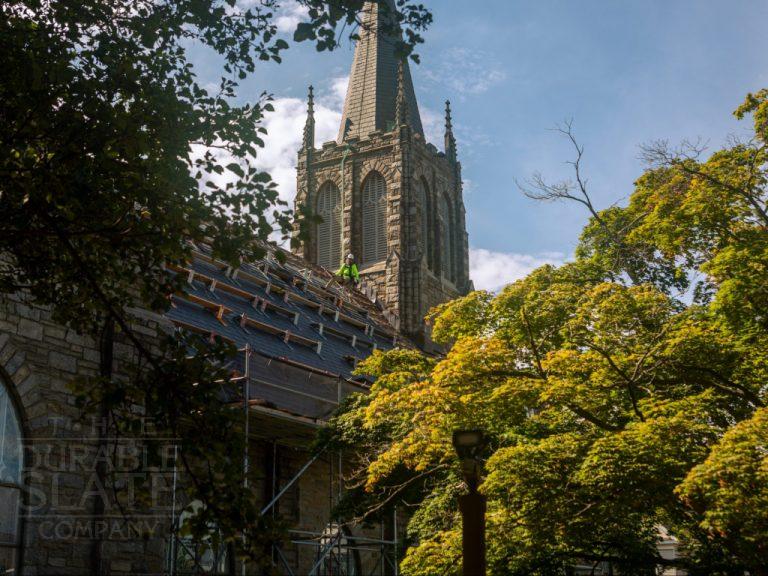

The Durable Slate Company designed and installed a new cupola on the 1889 Hotel Holmes in Westerville, Ohio. After the wood structure was hoisted up, assembled, and secured into place, a new copper roof and copper finial was installed. It was finished off with a copper lightning rod.

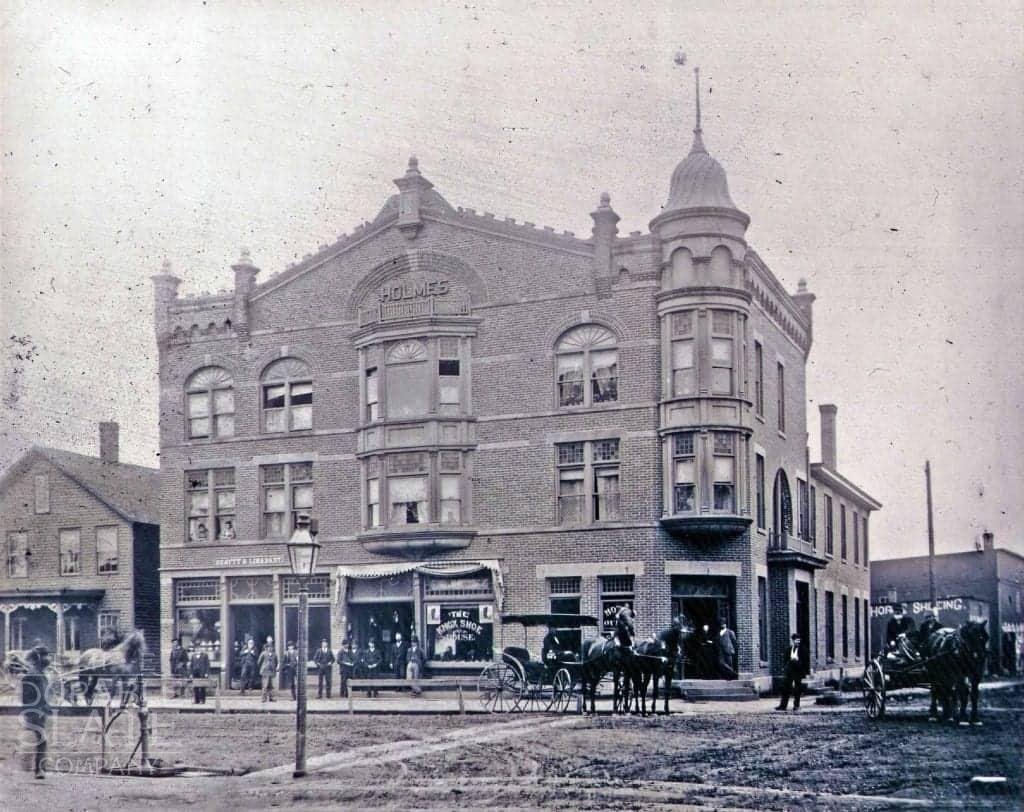

Thomas Holmes built a three-story Queen Anne-style hotel at the corner of Main and State Streets in Westerville, Ohio in 1889. This became the city’s “Landmark.” Unfortunately, this historic landmark was struck by lightning in the 1950s and the fantastic bell shaped dome that once adorned the main intersection of Westerville was removed. Luckily, the current owner of the building located an old postcard showing the original structure. Upon presenting it to The Durable Slate Company, initial drawings were drafted. After these drawings were approved by the City of Westerville Planning and Zoning Commission’s Review Board, work began.

Although the old postcard had no close-up details that would enable an exact duplication, it was very important to the owner that the general character, shape, and proportions were the same as the original. 2 inch by 12 inch wood studs were cut for the frame of the bell-shaped design. These wooden rafters had to have both concave and convex surfaces. Once cut, they were numbered, and partially assembled before being hoisted up on the roof top. Because of the location of the job, the city’s two main streets, Main and State, would have to be blocked off if a crane was used. Therefore, all the pieces were hoisted up to the roof by a rope and pulley system.

A full scale drawing of the diameter of the roof was drafted on a workbench inside The Durable Slate Company’s shop – then we went to work. To achieve the rounded surface, a 14-sided roof was constructed on top of a leveled surface. The skeleton of the cupola was separated into 3 different levels. After the entire frame was built, 1 inch by 4 inch tongue in groove wood was cut and screwed into position for the decking material. Nearly 800 of these trapezoids were cut, installed, numbered and removed to be transported. Once the wood was all on-site, it was lifted up and re-assembled in place. Ice and water membrane was installed as the underlayment to keep the wood dry prior to the copper roof installation.

Seventeen rows of copper panels were cut out of 20 ounce copper sheets. Each row had a different circumference; therefore, each row had a different size panel. There were 14 different sized panels in all. Each panel was 12 inches tall but with different widths. They started off at 24 inches wide at the bottom tapering to 3 inches wide at the top.

This diamond style panel system was all locked into place with copper cleats and has no solder on it except for the finial. The cleats coupled with the heavy 20 ounce copper allow the copper panels to move freely and yet be resilient against heavy winds. Adorning the top is a custom fabricated five foot tall finial. This was fabricated in the shop using copper balls supplied by W. F. Norman Company. The balls were soldered together with cones to make the ornament at the apex.

Topping it all off was a lightning rod system installed inside the finial that runs along the underside of the wooden base. A half inch copper cable extends from the finial to the exterior of the building and is grounded. This lightning rod will help to ensure against a repeat lightning strike like the one in the 1950s that robbed the city of the distinct look of their landmark.

For the finishing touch, the copper panels were buffed into a swirl pattern. This was done to replicate the swirls noted in the old postcard of the original cupola roof.

The Durable Slate Company’s superintendent on the job, Ron Ladina, was awarded the Craftsmanship of the Year Award from the Builder’s Exchange.